1.外观、表面应平整光滑,不允许有杂质和其他明显的缺陷,允许有轻微的擦伤,边缘应切割整齐,端面不得有分层和裂纹。

2.尺寸:面积不得小于380×480平方毫米,如需特殊规格,可同供需双方协议生产。其它数据详见机电部标准。标准规格1200*2400 1000*2000 特殊规格可根客户所需按图纸进行加工。

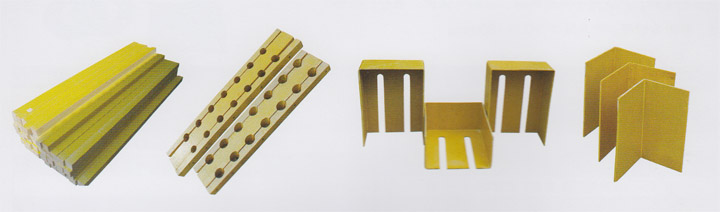

3.产品可根用户要求,加工成各种规格板、管、垫、法兰、瓦、等异形件。

1、外观 表面应平滑,无气泡、皱纹和裂纹。

2、标称厚度及允许偏差见表1。

表1 mm

<**** ****="width:715px;" cellspacing="0" cellpadding="0" border="1"> <****> <****> <**** ****="width:90.1pt;background-color:#cccccc;" colspan="2">标称厚度 <**** ****="width:108.4pt;background-color:#cccccc;">偏差 <**** ****="width:108.4pt;background-color:#cccccc;">标准厚度 <**** ****="width:101.55pt;background-color:#cccccc;">偏差 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">0.4 <**** ****="width:108.4pt;background-color:****ansparent;">±0.10 <**** ****="width:108.4pt;background-color:****ansparent;">8.0 <**** ****="width:101.55pt;background-color:****ansparent;">±0.72 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">0.5 <**** ****="width:108.4pt;background-color:****ansparent;">±0.12 <**** ****="width:108.4pt;background-color:****ansparent;">10.0 <**** ****="width:101.55pt;background-color:****ansparent;">±0.82 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">0.6 <**** ****="width:108.4pt;background-color:****ansparent;">±0.13 <**** ****="width:108.4pt;background-color:****ansparent;">12.0 <**** ****="width:101.55pt;background-color:****ansparent;">±0.94 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">0.8 <**** ****="width:108.4pt;background-color:****ansparent;">±0.16 <**** ****="width:108.4pt;background-color:****ansparent;">14.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.02 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">1.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.18 <**** ****="width:108.4pt;background-color:****ansparent;">16.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.12 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">1.2 <**** ****="width:108.4pt;background-color:****ansparent;">±0.20 <**** ****="width:108.4pt;background-color:****ansparent;">20.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.30 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">1.6 <**** ****="width:108.4pt;background-color:****ansparent;">±0.24 <**** ****="width:108.4pt;background-color:****ansparent;">25.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.50 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">2.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.28 <**** ****="width:108.4pt;background-color:****ansparent;">30.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.70 <****> <**** ****="width:90.1pt;background-color:****ansparent;" colspan="2">2.5 <**** ****="width:108.4pt;background-color:****ansparent;">±0.33 <**** ****="width:108.4pt;background-color:****ansparent;">35.0 <**** ****="width:101.55pt;background-color:****ansparent;">±1.95 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:88.95pt;background-color:****ansparent;">3.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.37 <**** ****="width:108.4pt;background-color:****ansparent;">40.0 <**** ****="width:101.55pt;background-color:****ansparent;">±2.10 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:88.95pt;background-color:****ansparent;">4.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.45 <**** ****="width:108.4pt;background-color:****ansparent;">45.0 <**** ****="width:101.55pt;background-color:****ansparent;">±2.30 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:88.95pt;background-color:****ansparent;">5.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.52 <**** ****="width:108.4pt;background-color:****ansparent;">50.0 <**** ****="width:101.55pt;background-color:****ansparent;">±2.45 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:88.95pt;background-color:****ansparent;">6.0 <**** ****="width:108.4pt;background-color:****ansparent;">±0.60 <**** ****="width:108.4pt;background-color:****ansparent;">60.0 <**** ****="width:101.55pt;background-color:****ansparent;">±2.50 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:88.95pt;background-color:****ansparent;"> <**** ****="width:108.4pt;background-color:****ansparent;"> <**** ****="width:108.4pt;background-color:****ansparent;">80.0 <**** ****="width:101.55pt;background-color:****ansparent;">±2.80 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:407.3pt;background-color:****ansparent;" colspan="4">注: 1 其他允许偏差可由供需双方协商。 2 对于标称厚度不在所列的优选厚度之一者,其允许偏差应采用下一个较大的优选厚度的偏差。

3、平直度见表2。表2 层压板表面距直尺的大允许偏差mm

<**** ****="width:715px;" cellspacing="0" cellpadding="0" border="1"> <****> <****> <**** ****="width:124.5pt;background-color:#cccccc;" rowspan="2">厚度 (d) <**** ****="width:277.5pt;background-color:#cccccc;" colspan="2">直尺长度 <****> <**** ****="width:5cm;background-color:#cccccc;">1000 <**** ****="width:135pt;background-color:#cccccc;">500 <****> <**** ****="width:124.5pt;background-color:****ansparent;">1.6≤d≤3 3<> 6<> 8< d <**** ****="width:5cm;background-color:****ansparent;">见注 10 8 6 <**** ****="width:135pt;background-color:****ansparent;">见注 2.5 2.0 1.5 <****> <**** ****="width:401.25pt;background-color:****ansparent;" colspan="3">>注:对标称厚度在1.6 mm≤d≤3 mm的允许偏差正在考虑之中

4、性能要求见表4。表4性能要求

<**** ****="width:715px;" cellspacing="0" cellpadding="0" border="1"> <****> <****> <**** ****="width:37.6pt;background-color:#cccccc;" colspan="2">序 号 <**** ****="width:149.7pt;background-color:#cccccc;">指 标 名 称 <**** ****="width:63.2pt;background-color:#cccccc;">单 位 <**** ****="width:73.7pt;background-color:#cccccc;">指 标 值 <**** ****="width:84.25pt;background-color:#cccccc;">说明 <****> <**** ****="width:37.6pt;background-color:****ansparent;" colspan="2">1 <**** ****="width:149.7pt;background-color:****ansparent;">垂直层向弯曲强度 <**** ****="width:63.2pt;background-color:****ansparent;">MPa <**** ****="width:73.7pt;background-color:****ansparent;">≥340 <**** ****="width:84.25pt;background-color:****ansparent;">- <****> <**** ****="width:37.6pt;background-color:****ansparent;" colspan="2">2 <**** ****="width:149.7pt;background-color:****ansparent;">平行层向冲击强度 (简支梁法) <**** ****="width:63.2pt;background-color:****ansparent;">KJ/ <**** ****="width:73.7pt;background-color:****ansparent;">≥33 <**** ****="width:84.25pt;background-color:****ansparent;" rowspan="2">两者之一满足本标准要求即可 <****> <**** ****="width:37.6pt;background-color:****ansparent;" colspan="2">3 <**** ****="width:149.7pt;background-color:****ansparent;">平行层向冲击强度 (悬臂梁法) <**** ****="width:63.2pt;background-color:****ansparent;">kJ/ <**** ****="width:73.7pt;background-color:****ansparent;">≥34 <****> <**** ****="width:37.6pt;background-color:****ansparent;" colspan="2">4 <**** ****="width:149.7pt;background-color:****ansparent;">垂直层向电气强度 (90℃±2℃油中) <**** ****="width:63.2pt;background-color:****ansparent;">MV/m <**** ****="width:73.7pt;background-color:****ansparent;">见表5 <**** ****="width:84.25pt;background-color:****ansparent;">- <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">5 <**** ****="width:149.7pt;background-color:****ansparent;">平行层向击穿电压 (90℃±2℃油中) <**** ****="width:63.2pt;background-color:****ansparent;">kV <**** ****="width:73.7pt;background-color:****ansparent;">≥35 <**** ****="width:84.25pt;background-color:****ansparent;">- <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">6a <**** ****="width:149.7pt;background-color:****ansparent;">介电常数 (48Hz-62Hz以下) <**** ****="width:63.2pt;background-color:****ansparent;">- <**** ****="width:73.7pt;background-color:****ansparent;">≤5.5 <**** ****="width:84.25pt;background-color:****ansparent;" rowspan="2">两者之一满足本标准要求即可 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">6b <**** ****="width:149.7pt;background-color:****ansparent;">介电常数 (1MHz以下) <**** ****="width:63.2pt;background-color:****ansparent;">- <**** ****="width:73.7pt;background-color:****ansparent;">≤5.5 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">7 <**** ****="width:149.7pt;background-color:****ansparent;">马丁温度纵向 <**** ****="width:63.2pt;background-color:****ansparent;">℃ <**** ****="width:73.7pt;background-color:****ansparent;">≥200 <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">8 <**** ****="width:149.7pt;background-color:****ansparent;">热稳定性 <**** ****="width:63.2pt;background-color:****ansparent;">℃ <**** ****="width:73.7pt;background-color:****ansparent;">200 <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">9 <**** ****="width:149.7pt;background-color:****ansparent;">耐油性变压器油中4h <**** ****="width:63.2pt;background-color:****ansparent;">℃ <**** ****="width:73.7pt;background-color:****ansparent;">130 <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">10 <**** ****="width:149.7pt;background-color:****ansparent;">拉伸强度纵向 横向 <**** ****="width:63.2pt;background-color:****ansparent;">MPa <**** ****="width:73.7pt;background-color:****ansparent;">≥314 ≥216 <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">11 <**** ****="width:149.7pt;background-color:****ansparent;">粘合强度 <**** ****="width:63.2pt;background-color:****ansparent;">N <**** ****="width:73.7pt;background-color:****ansparent;">≥5600 <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">12 <**** ****="width:149.7pt;background-color:****ansparent;">表面电阻率常态时 浸水后 <**** ****="width:63.2pt;background-color:****ansparent;">MΩ <**** ****="width:73.7pt;background-color:****ansparent;">≥1× ≥1× <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">13 <**** ****="width:149.7pt;background-color:****ansparent;">体积电阻率常态时 浸水后 <**** ****="width:63.2pt;background-color:****ansparent;">MΩ·m <**** ****="width:73.7pt;background-color:****ansparent;">≥1× ≥1× <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">14 <**** ****="width:149.7pt;background-color:****ansparent;">平行层向绝缘电阻常态时 浸水后 <**** ****="width:63.2pt;background-color:****ansparent;">MΩ <**** ****="width:73.7pt;background-color:****ansparent;">≥1× ≥1× <**** ****="width:84.25pt;background-color:****ansparent;"> <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">15a <**** ****="width:149.7pt;background-color:****ansparent;">介质损耗因数 (48Hz-62Hz以下) <**** ****="width:63.2pt;background-color:****ansparent;">- <**** ****="width:73.7pt;background-color:****ansparent;">≤0.04 <**** ****="width:84.25pt;background-color:****ansparent;" rowspan="2">两者之一满足本标准要求即可 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">15b <**** ****="width:149.7pt;background-color:****ansparent;">介质损耗因数 (1MHz以下) <**** ****="width:63.2pt;background-color:****ansparent;">- <**** ****="width:73.7pt;background-color:****ansparent;">≤0.04 <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">16 <**** ****="width:149.7pt;background-color:****ansparent;">浸水后绝缘电阻 <**** ****="width:63.2pt;background-color:****ansparent;">Ω <**** ****="width:73.7pt;background-color:****ansparent;">≥5.0× <**** ****="width:84.25pt;background-color:****ansparent;">- <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">17 <**** ****="width:149.7pt;background-color:****ansparent;">密度 <**** ****="width:63.2pt;background-color:****ansparent;">g/ <**** ****="width:73.7pt;background-color:****ansparent;">(1.7-1.9) <**** ****="width:84.25pt;background-color:****ansparent;">- <****> <**** ****="background-color:****ansparent;"> <**** ****="width:36.45pt;background-color:****ansparent;">18 <**** ****="width:149.7pt;background-color:****ansparent;">吸水性 <**** ****="width:63.2pt;background-color:****ansparent;">mg <**** ****="width:73.7pt;background-color:****ansparent;">见表6 <**** ****="width:84.25pt;background-color:****ansparent;">-

表5垂直层向电气强度

<**** ****="width:715px;" cellspacing="0" cellpadding="0" border="1"> <****> <****> <**** ****="width:64.05pt;background-color:#cccccc;">平均厚度 mm <**** ****="width:140.2pt;background-color:#cccccc;">电气强度 MV/m <**** ****="width:64pt;background-color:#cccccc;">厚度 mm <**** ****="width:140.2pt;background-color:#cccccc;">电气强度 MV/m <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.4 <**** ****="width:140.2pt;background-color:#cccccc;">≥16.9 <**** ****="width:64pt;background-color:#cccccc;">1.6 <**** ****="width:140.2pt;background-color:#cccccc;">≥12.7 <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.5 <**** ****="width:140.2pt;background-color:#cccccc;">≥16.1 <**** ****="width:64pt;background-color:#cccccc;">1.8 <**** ****="width:140.2pt;background-color:#cccccc;">≥12.2 <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.6 <**** ****="width:140.2pt;background-color:#cccccc;">≥15.6 <**** ****="width:64pt;background-color:#cccccc;">2.0 <**** ****="width:140.2pt;background-color:#cccccc;">≥11.8 <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.7 <**** ****="width:140.2pt;background-color:#cccccc;">≥15.2 <**** ****="width:64pt;background-color:#cccccc;">2.2 <**** ****="width:140.2pt;background-color:#cccccc;">≥11.4 <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.8 <**** ****="width:140.2pt;background-color:#cccccc;">≥14.8 <**** ****="width:64pt;background-color:#cccccc;">2.4 <**** ****="width:140.2pt;background-color:#cccccc;">≥11.1 <****> <**** ****="width:64.05pt;background-color:#cccccc;">0.9 <**** ****="width:140.2pt;background-color:#cccccc;">≥14.5 <**** ****="width:64pt;background-color:#cccccc;">2.5 <**** ****="width:140.2pt;background-color:#cccccc;">≥10.9 <****> <**** ****="width:64.05pt;background-color:#cccccc;">1.0 <**** ****="width:140.2pt;background-color:#cccccc;">≥14.2 <**** ****="width:64pt;background-color:#cccccc;">2.6 <**** ****="width:140.2pt;background-color:#cccccc;">≥10.8 <****> <**** ****="width:64.05pt;background-color:#cccccc;">1.2 <**** ****="width:140.2pt;background-color:#cccccc;">≥13.7 <**** ****="width:64pt;background-color:#cccccc;">2.8 <**** ****="width:140.2pt;background-color:#cccccc;">≥10.5 <****> <**** ****="width:64.05pt;background-color:#cccccc;">1.4 <**** ****="width:140.2pt;background-color:#cccccc;">≥13.2 <**** ****="width:64pt;background-color:#cccccc;">3.0 <**** ****="width:140.2pt;background-color:#cccccc;">≥10.2

注:1 对90℃±2℃油中垂直层向电气强度,可任选20s逐级升压和1min耐压试验要求中的一种。对符合二者之一要求的材料,应视其90℃±2℃油中垂直层向电气强度是符合本标准要求的。 2 如果测得的试样厚度算术平均值是介于表中两厚度之间,则其指标值应从内插法求取。如果测得的厚度算术平均值小于0.4mm,则其电气强度指标值取≥16.9MV/m。如果标称厚度为3mm,并且测得的厚度算术平均值大于3mm时,则其电气强度的指标值取≥10.2MV/m表6吸水性

<**** ****="margin:auto auto auto 1.15pt;width:656px;" cellspacing="0" cellpadding="0" border="1"> <****> <****> <**** ****="width:161.85pt;background-color:#cccccc;">试样厚度平均值 mm <**** ****="width:73.9pt;background-color:#cccccc;">吸水性 mg <**** ****="width:161.85pt;background-color:#cccccc;">试样厚度平均值 mm <**** ****="width:73.9pt;background-color:#cccccc;">吸水性 mg <****> <**** ****="width:161.85pt;background-color:****ansparent;">0.4 <**** ****="width:73.9pt;background-color:****ansparent;">≤17 <**** ****="width:161.85pt;background-color:****ansparent;">5 <**** ****="width:73.9pt;background-color:****ansparent;">≤25 <****> <**** ****="width:161.85pt;background-color:****ansparent;">0.5 <**** ****="width:73.9pt;background-color:****ansparent;">≤17 <**** ****="width:161.85pt;background-color:****ansparent;">6 <**** ****="width:73.9pt;background-color:****ansparent;">≤27 <****> <**** ****="width:161.85pt;background-color:****ansparent;">0.6 <**** ****="width:73.9pt;background-color:****ansparent;">≤17 <**** ****="width:161.85pt;background-color:****ansparent;">8 <**** ****="width:73.9pt;background-color:****ansparent;">≤31 <****> <**** ****="width:161.85pt;background-color:****ansparent;">0.8 <**** ****="width:73.9pt;background-color:****ansparent;">≤18 <**** ****="width:161.85pt;background-color:****ansparent;">10 <**** ****="width:73.9pt;background-color:****ansparent;">≤34 <****> <**** ****="width:161.85pt;background-color:****ansparent;">1.0 <**** ****="width:73.9pt;background-color:****ansparent;">≤18 <**** ****="width:161.85pt;background-color:****ansparent;">12 <**** ****="width:73.9pt;background-color:****ansparent;">≤38 <****> <**** ****="width:161.85pt;background-color:****ansparent;">1.2 <**** ****="width:73.9pt;background-color:****ansparent;">≤18 <**** ****="width:161.85pt;background-color:****ansparent;">14 <**** ****="width:73.9pt;background-color:****ansparent;">≤41 <****> <**** ****="width:161.85pt;background-color:****ansparent;">1.6 <**** ****="width:73.9pt;background-color:****ansparent;">≤19 <**** ****="width:161.85pt;background-color:****ansparent;">16 <**** ****="width:73.9pt;background-color:****ansparent;">≤46 <****> <**** ****="width:161.85pt;background-color:****ansparent;">2.0 <**** ****="width:73.9pt;background-color:****ansparent;">≤20 <**** ****="width:161.85pt;background-color:****ansparent;">20 <**** ****="width:73.9pt;background-color:****ansparent;">≤52 <****> <**** ****="width:161.85pt;background-color:****ansparent;">2.5 <**** ****="width:73.9pt;background-color:****ansparent;">≤21 <**** ****="width:161.85pt;background-color:****ansparent;">25 <**** ****="width:73.9pt;background-color:****ansparent;">≤61 <****> <**** ****="width:161.85pt;background-color:****ansparent;">3 <**** ****="width:73.9pt;background-color:****ansparent;">≤22 <**** ****="width:161.85pt;background-color:****ansparent;">单面加工至22.5 <**** ****="width:73.9pt;background-color:****ansparent;">≤73 <****> <**** ****="width:161.85pt;background-color:****ansparent;">4 <**** ****="width:73.9pt;background-color:****ansparent;">≤23 <**** ****="width:73.9pt;background-color:****ansparent;">

注:1如果测得的试样厚度算术平均值是介于表中两厚度之间,则其指标值应从内插法求得。2如果测得的厚度算术平均值小于0.4mm,则其指标值取≤17mg。如果标称厚度为25mm并测得的厚度算术平均值大于25mm时,则其指标值取≤61mg。标称厚度大于25mm的板材,则应从单面加工至22.5mm且加工面应是比较光滑的。

是由电工用无碱玻璃纤维布浸以环氧酚醛树脂,经烘焙、热压而成。

具有较高的机械和介电性能,较好的耐热性和耐潮性,并有良好的机械加工性,耐热等级为B级。

适用于电机、电器设备中作为绝缘结构零部件,并可在潮温环境和变压器油中使用。

以较高的机械性能和电气性能,广泛应用在发电机、马达、电子器具上作为绝缘材料和构件。在变压器油压环境和湿度环境中也非常适用。

7、环氧树脂和所用的固化剂的反应是通过直接加成反应或树脂分子中环氧基的开环聚合反应来进行的,没有水或其它挥发性副产物放出。它们和不饱和聚酯树脂、酚醛树脂相比,在固化过程中显示出很低的收缩性(小于2%)。